The Ultimate Guide to China Injection Molding for Metal Fabricators

China injection molding has become a cornerstone in the manufacturing and metal fabrication industries, offering businesses unparalleled opportunities to enhance their operations. Whether you are a small startup or an established company, understanding the ins and outs of this method can pave the way for increased efficiency, reduced costs, and higher product quality. In this comprehensive guide, we’ll delve into the various facets of injection molding in China and how it impacts the global market.

What is Injection Molding?

Injection molding is a manufacturing process that involves injecting molten material into a mold to create parts and products. This technique is widely used for producing a variety of items, but it particularly excels in the production of complex metal parts due to its precision and speed.

Why Choose China for Injection Molding?

China has emerged as a leader in the injection molding industry for several reasons:

- Cost Efficiency: Labor costs in China are typically lower than in many Western countries, allowing businesses to save significantly on production expenses.

- Advanced Technology: Many Chinese manufacturers have adopted cutting-edge technology in their injection molding processes, ensuring high-quality products.

- Scalability: Chinese manufacturers can easily scale production to meet the demands of various sized businesses, whether they require small batch sizes or high-volume production.

- Quick Turnaround: With a mature supply chain and experienced labor force, Chinese manufacturers can achieve faster turnaround times, helping companies launch products to market swiftly.

The China Injection Molding Process

The China injection molding process typically involves several key steps:

1. Designing the Mold

The first step is designing the mold, which involves creating a digital 3D representation of the component that will be produced. This design is crucial as it will determine the final quality of the product.

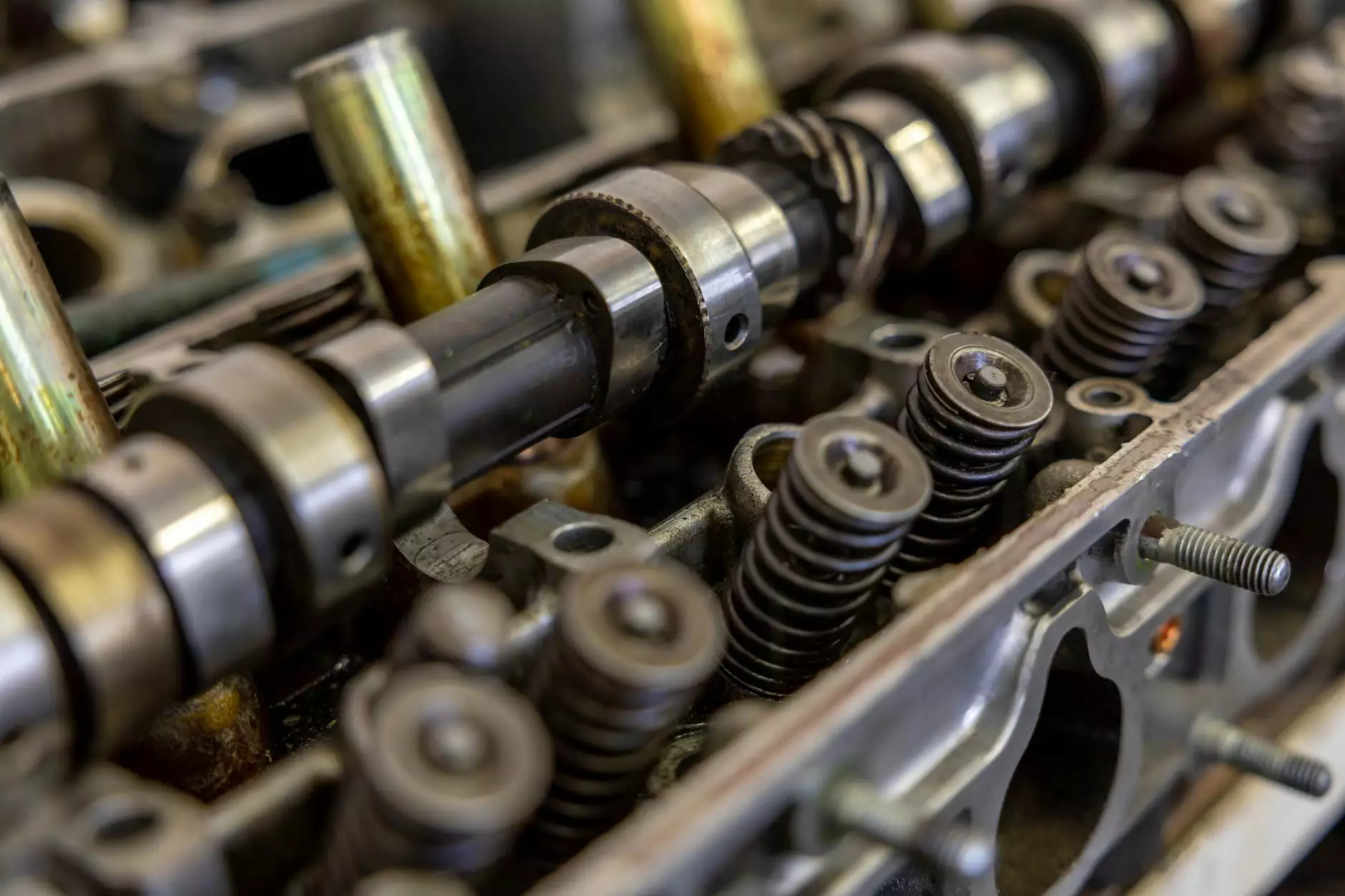

2. Mold Production

Once the design is approved, the mold is manufactured, often using precision machining techniques. High-quality molds are essential for producing parts that meet exact specifications.

3. Injection Phase

In this phase, the chosen material (plastic, metal, etc.) is heated until it becomes molten. This molten material is injected into the mold under high pressure.

4. Cooling and Solidification

After the material has been injected, it is allowed to cool and solidify in the mold. This phase is critical to ensure the integrity of the final product.

5. Part Ejection

Once the product has cooled and solidified, it is ejected from the mold. This step requires careful handling to avoid damaging the part.

6. Finishing Touches

Finally, there may be additional processes such as surface finishing, painting, or assembly, depending on the product specifications.

Benefits of China Injection Molding for Metal Fabricators

The utilization of China injection molding for metal fabrication comes with a myriad of benefits:

- Reduced Production Costs: Lower labor and material costs can significantly impact the bottom line.

- High Precision and Accuracy: The injection molding process allows for extremely precise production, making it ideal for complex parts.

- Diverse Materials: Manufacturers can work with a variety of thermoplastics and metal alloys, which can enhance the final product's performance.

- Environmental Considerations: Innovations in materials and production techniques have led to more sustainable practices in the industry.

Challenges of China Injection Molding

While there are many advantages, it's also important to consider the challenges associated with injection molding in China:

- Quality Control: Ensuring that the manufacturing partner adheres to quality standards is essential to prevent defects.

- Language Barrier: Communication can be a hurdle, particularly when discussing technical specifications and requirements.

- Intellectual Property Risks: Protecting your designs and innovations is crucial when working with overseas manufacturers.

How to Select the Right Partner in China?

Choosing the right partner for your injection molding needs is a critical decision. Here are some factors to consider:

1. Experience and Expertise

Look for manufacturers with a proven track record in injection molding. Experience in your specific industry can be particularly beneficial.

2. Certifications and Quality Standards

Ensure that potential partners meet international quality standards and possess relevant certifications (like ISO).

3. Technology and Equipment

Investigate the technology and machinery used by the manufacturer's facility. High-quality machines can lead to superior products.

4. Communication

Effective communication is vital; ensure that the manufacturer can understand and respond to your needs accurately.

5. Samples and Prototyping

Ask for samples of their previous work and, if necessary, request prototyping services to evaluate their capabilities before committing.

Innovations in China Injection Molding

The injection molding industry is continuously evolving, and China is at the forefront of several innovations:

- Advanced Materials: Development of new polymers and composites that are stronger and more lightweight.

- Smart Manufacturing: Adoption of Industry 4.0 technologies, including IoT and AI for process optimization.

- 3D Printing Integration: Combining additive manufacturing with injection molding for complex designs that were previously impossible.

Future Trends in Injection Molding

As the industry evolves, several trends are likely to shape the future of China injection molding:

- Sustainability: Growing emphasis on eco-friendly materials and processes to minimize environmental impact.

- Customization: Increased demand for customized products, leading to more flexible manufacturing processes.

- Globalization: As companies look to source products from international manufacturers, the importance of reliable partners in China will continue to rise.

Conclusion: The Impact of China Injection Molding on Your Business

In conclusion, China injection molding offers metal fabricators significant opportunities for innovation, cost savings, and market competitiveness. By understanding the process, selecting the right manufacturing partners, and keeping up with industry trends, your business can thrive in today’s competitive landscape.

For those looking to leverage injection molding for their projects, stay informed about advancements in technology and best practices. Companies like Deep Mould (found at deepmould.net) can provide valuable resources and support in navigating this crucial manufacturing method.